Die Tost-Sollbruchstellen in optimierter Form haben folgende Qualitätsmerkmale:

- längere Lebensdauer

- korrekte Kennzeichnung mit Lastgruppe und Herstellermarkierung

- gefertigt aus hochwertigem Luftfahrt-Stahl mit Zertifikat

- eindeutige Unterscheidung von minderwertigen Plagiaten

- Fertigungstoleranz von nur 5% (in den Vorschriften werden 10 % gefordert)

Wie für mustergeprüfte Geräte selbstverständlich, erfolgt auch die Fertigung der Sollbruchstellen nach den Regeln unseres EASA-zugelassenen Herstellungsbetriebes. Jede Charge wird auf computergesteuerten Prüfmaschinen getestet, das Ergebnis dokumentiert und damit gleich bleibende Qualität und Rückverfolgbarkeit garantiert.

Wichtige Hinweise

- Sollbruchstellen schützen Ihr Flugzeug vor Überlastung

- Benützen Sie immer die im Kennblatt oder Flughandbuch geforderten Sollbruchstellen

- Die Überprüfung des Seilvorspannes ist nach SBO vor Beginn des Flugbetriebes vorgeschrieben, das schließt auch die Sollbruchstellen mit ein

- Die Betriebszeit der Sollbruchstellen endet mit jeder sichtbaren Beschädigung bzw. Verformung

- Wir empfehlen, Sollbruchstellen nach 200 Starts grundsätzlich zu erneuern.

- Eine rechtzeitig getausche Sollbruchstelle ist immer günstiger und sicherer als eine einzelne Startunterbrechung.

- Immer Schutzhülse verwenden

- Nur die passenden Schäkel verwenden: das Verklemmen von Sollbruch-Einsatz und Schutzhülse wir so verhindert und damit die undefinierte Erhöhung der Bruchlast

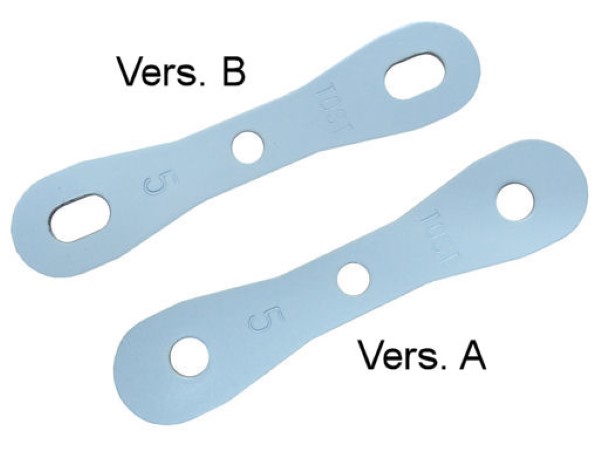

- Bei Reserveschaltung immer einen Rundloch- und einen Langloch-Einsatz verwenden, sonst verdoppelt sich die Bruchlast!

Warnung: bei Kombination von Sollbruchstellen unterschiedlicher Hersteller kann sich die Bruchlast wegen der Längenänderung (Dehnung) minderwertiger Einsätze verdoppeln!